Christopher

Member

Registered: 14th Oct 10

Location: Eastbourne

User status: Offline

|

Wow! Never fails to amaze me reading these! Everything is done so quickly too! Look forward to seeing this start piecing back together!

|

rustyarchs

Member

Registered: 29th Aug 04

Location: scotland

User status: Offline

|

watching this one as well! buggers so talented

|

SVM 286

Member

Registered: 13th Feb 05

Location: pain

User status: Offline

|

Strange feeling of De Ja Vu in this thread

And just when his skills have boggled my mind as much as I think they can... he goes and boggles it some more.

He certainly doesn't tire or get bored easily does he.

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

quote:

Originally posted by SVM 286

He certainly doesn't tire or get bored easily does he.

He has had this one planned before the other was even finished. No chance him getting bored, be a few years work in this one.

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

M Sutton

Member

Registered: 11th Jan 03

Location: Northamptonshire

User status: Offline

|

Amazing skills! Wish I had his talent!!!!

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

Hamish has been cracking on with some more work on the car lately.

Got the last of the jig made up. Front turret bars are now done with the same process as the rears.

Tied up the rear panel so it can be replaced with the new carbon/ kevlar one, thanks to Andy Krinks for the rear panel.

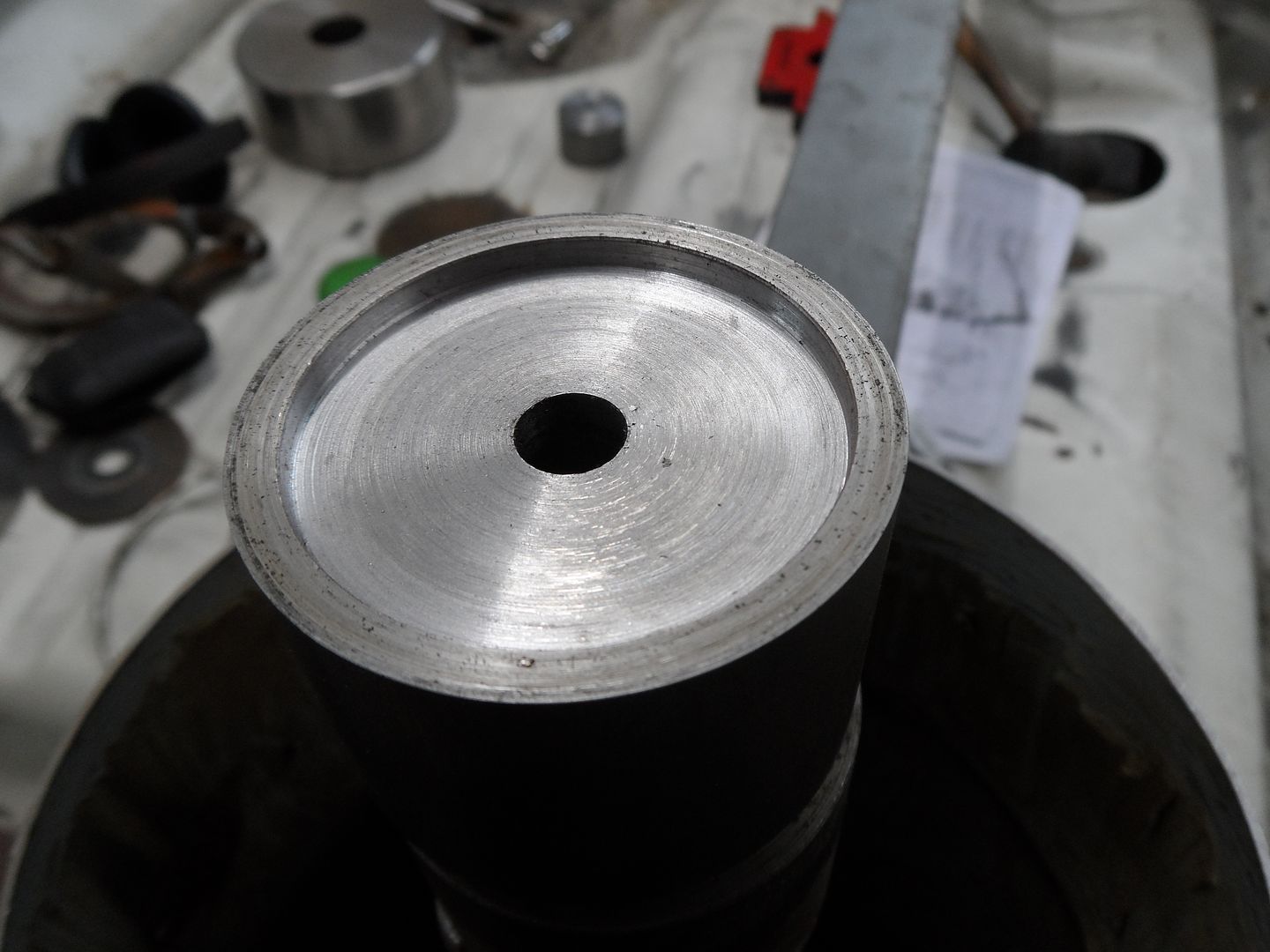

Next up was a little work on the lathe. Top mounts for the rear turrets machined from billet. They raise the mounting point 40mm and give a flat top for using proper camber adjustable mounts. They are 3mm thick so can weld direct to them as per the MSA regs.

Then machined up the required 40mm spacers which locate onto the jig struts and chopped off the original mounts.

A little bit of welding and grinding and the top was done, the strut require slight massaging to get it round for the top mount.

He's hoping to get a little work done over the Christmas break. Getting the scuttle/ A pillars welded back into place is the next job. Then he will move onto the rear panel and getting the roof into its proper position.

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

Paul_JC

Member

Registered: 28th Jan 09

Location: Corby

User status: Offline

|

never fails to amaze me the work this guy does

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

Time for an update on this build.

Hamish ordered up the roll cage tubing at the start of January. Big thanks to Joe at Proformance metals www.proformancemetals.co.uk for sorting me a great price. The tubing is proper T45 grade not the fake stuff that is doing the rounds. It is 1.750" x 12swg (44.45 x 2.6mm). With the tubing here he needed some templates so the tube could be bent to shape. Decided to use wood for the main hoop template, got it nice and tight to the B pillars so it can support them.

So that was delivered to Protection and performance with a jig for the A pillars. It took 4 weeks to get bent as they were so busy hence not doing much with the car lately. He had the pieces bent with 250mm added to the legs so they come through the floor. These will be used as jacking points and to weld the sill tubes to.

So this weekend it was time to get the cage into place. Big thanks to Jamie (Squib) for his help today!

Nice and tight to the A pillars:

So that is where its up to at the moment. Next job are the rear stays from the hoop onto the new turrets. This will finally put some strength back into the shell and the cage can develop from there.

He bought a pair of top mounts for the rear so can get the tubing in the right place as he wants it to sit on top slightly. They are actually designed for a mk2 escort and have huge 20mm aurora bearings in them. He's going to have these bolted to the top of the turrets like modern wrc cars for easy of adjustability.

Hopefully should get cracked on with the build at a faster pace now!

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

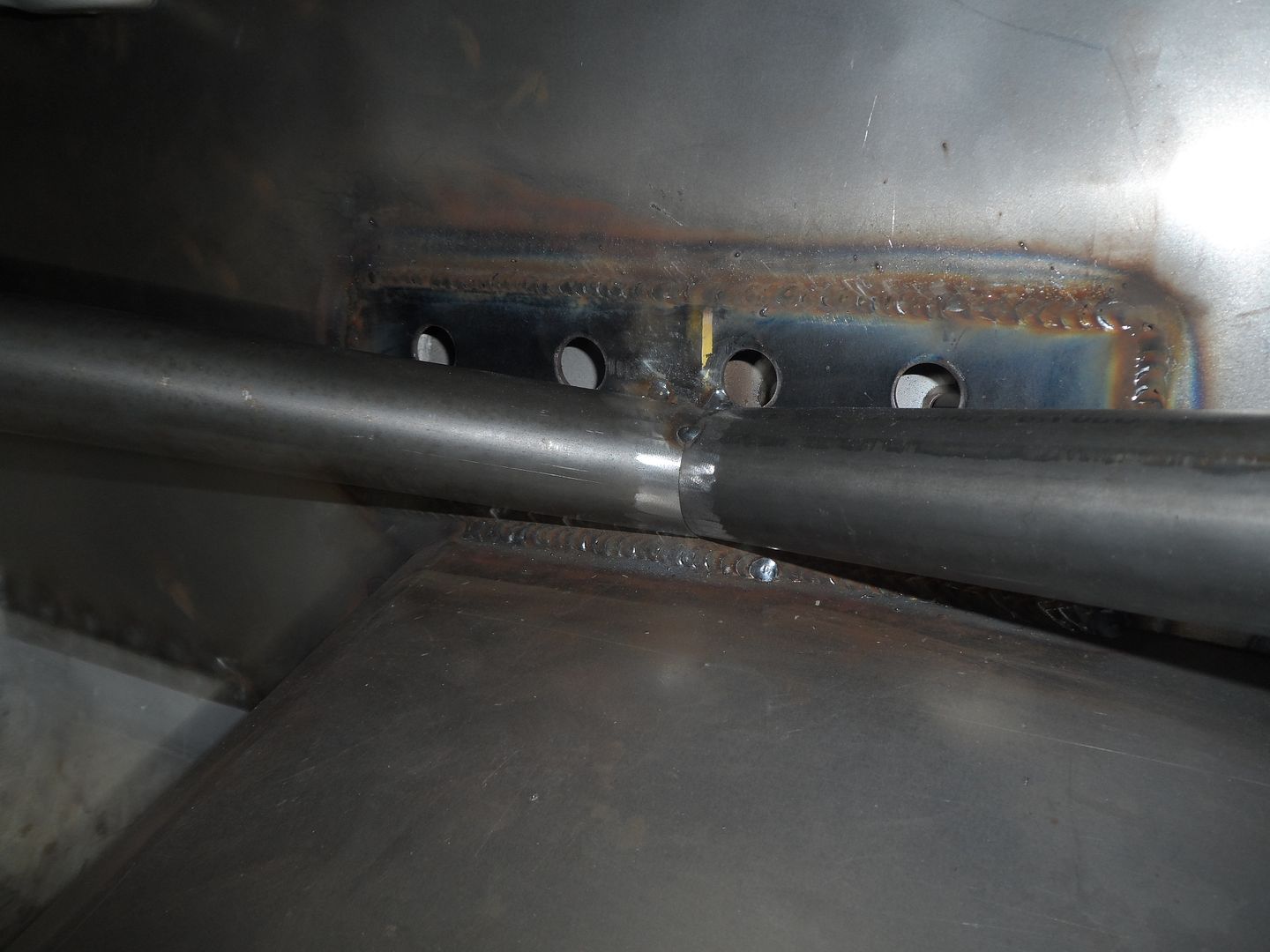

Hamish has finally had some time to get stuck into this build again, the core of the cage notched and tacked in place.

Tubes are notched so they sit up on the lip of the suspension turret to help with strength. Spaced the bars out to spread the load so they dont tip under bit load.

He's very happy with how the cage has gone inside whats left of the shell. Its very tight to the A and B pillars and the main hoop is hidden by the B pillar from the side profile. Almost ready to order up the small diameter tube now!

He decided to put a bar in at the base of the main hoop. This obviously adds massive side impact strength and ties the 2 floor pans together at the same time. Also going to use it to pick up for the rear seat mounting.

Firstly the floor got cut back to sink the bar into:

Took a bad picture of a notch all done with a grinder:

Then welded the bar in place and cut some floor sections:

Underside of the floor/ tube tacked together. This will be welded and smoothed off. The main hoop will be cut back but left slightly low as a jacking point.

Its coming along nicely now. Next big job is to weld the scuttle/ A pillars into position then the A pillar bars can be welded in to complete the core of the cage.

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

Hamish has been back working on this shell for the past couple of days. Another thanks to Joe at Proformance metals www.proformancemetals.co.uk for sorting me out with 25 meters of 40 x 2mm T45 tubing for the rest of the cage. This meant he has been able to start on all the rest of the tubes in the shell.

To go with this he managed by luck to pick up a 2 door Audi 80 roof and doors which he could not turn down. The roof and doors will go into storage for the future on another shell. It has however allowed him to fit up the doors so could make sure the scuttle and A pillars went on in the correct position.

Doors in the hole and scuttle/ A pillars welded into position:

A pillar bars run along the top of the door aperture which will be welded to it to get the door shut perfect:

The roof was cut out at the top of the screen to get the A pillar bars up high. He then made up a plate with a swage in to cover up the hole and tie it into the A pillar bar:

Added a roof cross in with the 40mm tubing

Then a couple of bars from the rear turrets to the base of the main hoop. These touch the inner arch tubs which they will be welded into.

The next job is to get the door bars bent up as these set the height of a few other bars coming off the main hoop and A pillars. Then it will be a raised rear floor to get the diff higher and get the cage dropped down to hold it. Coming along nicely now, very much enjoying the build at the moment.

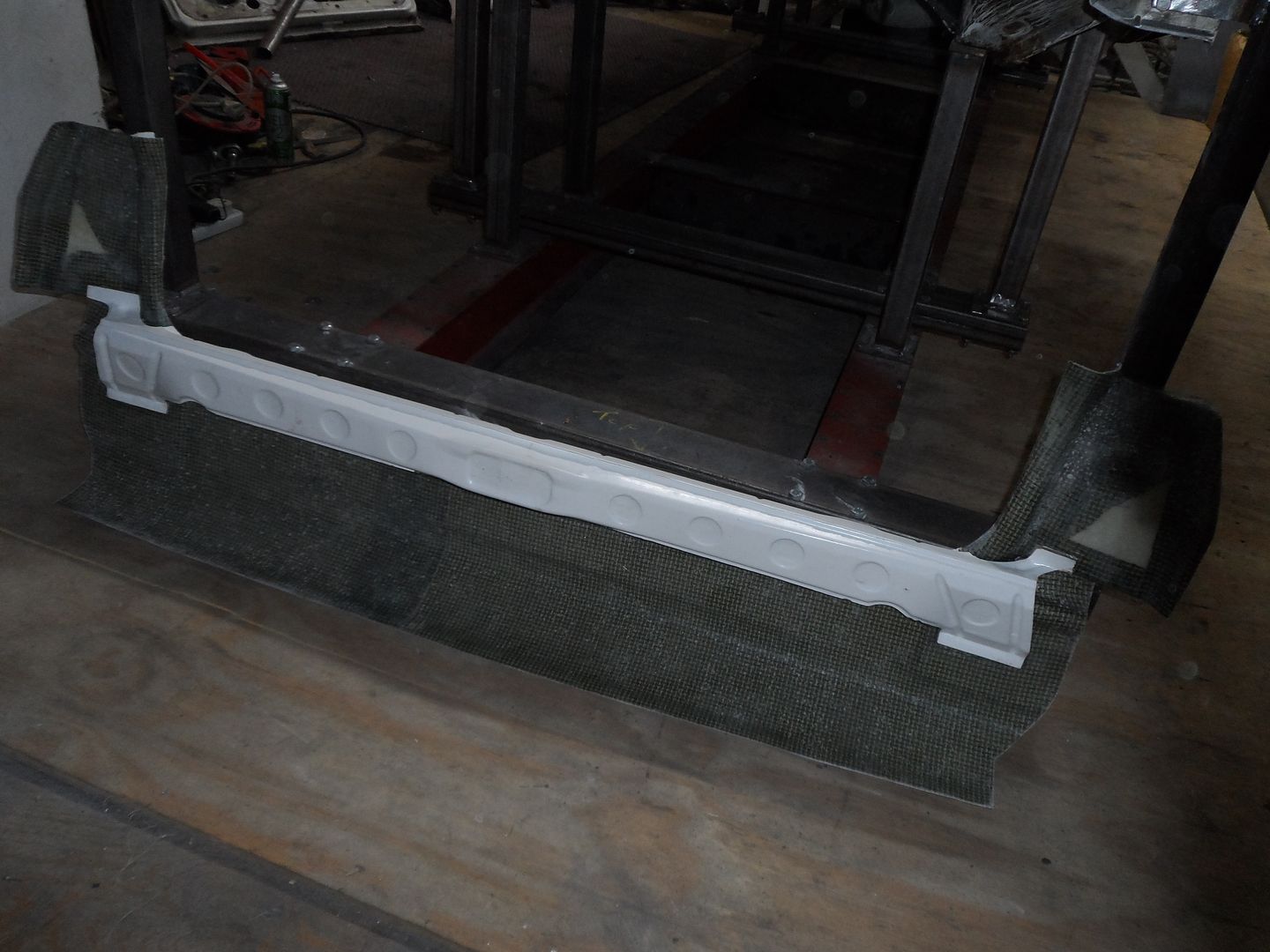

Had a couple of days to work on the shell over the weekend and got a bit done. First job was to run a bar down each sill from the main hoop to the A pillar. He decided he wanted one inside the sill down as low as possible for any side protection and also to strengthen up the frame.

So the spot welds were drilled out and the sill folded open. They were in very good condition inside which was heartening considering the shell had spent a long time outside.

The strengthening was then cut out as it was in the way of the bar and is not needed with the space frame. He also welded up the holes for the trim pieces and gave it a dusting of paint to stop any rust from coming through.

Bar notched and in place

Then it was sealed back up again.

The same with the other side which was even cleaner inside.

Next he made up some brackets to hold the door opening onto the main hoop and also act as a piece for the striker pin to attach to. The metal door frame will be replaced with the composite rear wings hence needing something to locate them when the time comes.

Final job of the weekend was to add the dash bar into the cage.

Starting to take shape now.

Hamish had a measure up and has ordered up a pair of doors bars to be bent. They should be here next week which will really tie the A pillars to the main hoop. Next job is to cut the rear floor out so a new raised section can go in and then start dropping bars to it to hang the diff from.

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

Gary

Premium Member

Registered: 22nd Nov 06

Registered: 22nd Nov 06

Location: West Yorkshire

User status: Offline

|

Skills

|

corsadonk

Premium Member

Registered: 4th Jul 09

Location: Marlborough, Wiltshire

User status: Offline

|

Pretty dam cool!

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

Door bars turned up last week so they have been notched and fitted. The lowers are bent at 30 degrees and the uppers at 50 to make them lower at the centre making them easier to climb over. Lowered a little over the other car as they are slightly too high in it for his elbow. With those in place it enabled the bars from the hoop to the turrets to go into place. He needed these points as the rear diff pick ups will come down from this location. He has left the bars just pushed into place so they can be lifted out for better access inside.

He's very happy with how the cage/ spaceframe is looking. The next job is to remove the rear floor and fit up the new raised section into place.

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

M Sutton

Member

Registered: 11th Jan 03

Location: Northamptonshire

User status: Offline

|

Very impressive!

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

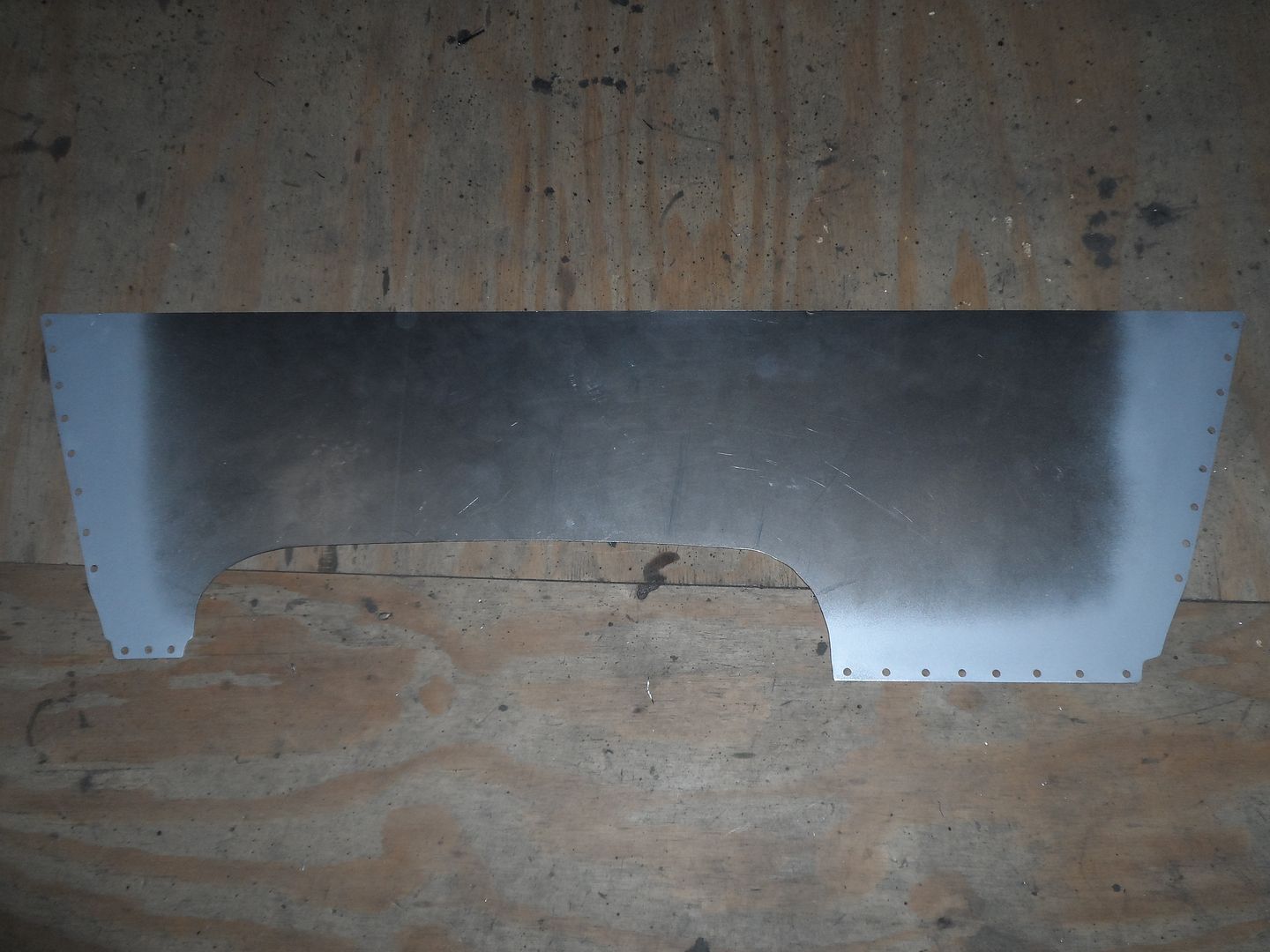

Hamish had some more time on the car this weekend. The rear floor area had to go due to wanting to run the rear diff higher to level out the drive shaft angles. The new floor is 60mm higher than the old one which gives plenty of scope to get the shafts level even when running the car very low.

The old floor chopped out, left quite a hole!

Bit of a mess around with a spare diff to see if any of the front floor would need to go but its going to work fine as it is.

So with the old floor out of the way he had a new floor folded up. This is supported on posts from the jig so knows its gone in flat and true.

The new floor in place just tacked in for now:

The vertical section will have a return lip welded on to continue the inner arch line:

The floor goes that far back at the same height so the rear anti roll bar car fit in without any cutting like had to happen on the other car. Delighted with how it has gone in and its removed a lot of rust from the rear end. The next job on the list is to make up a jig for the diff mounting points and extend the cage down to the floor to pick these up.

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

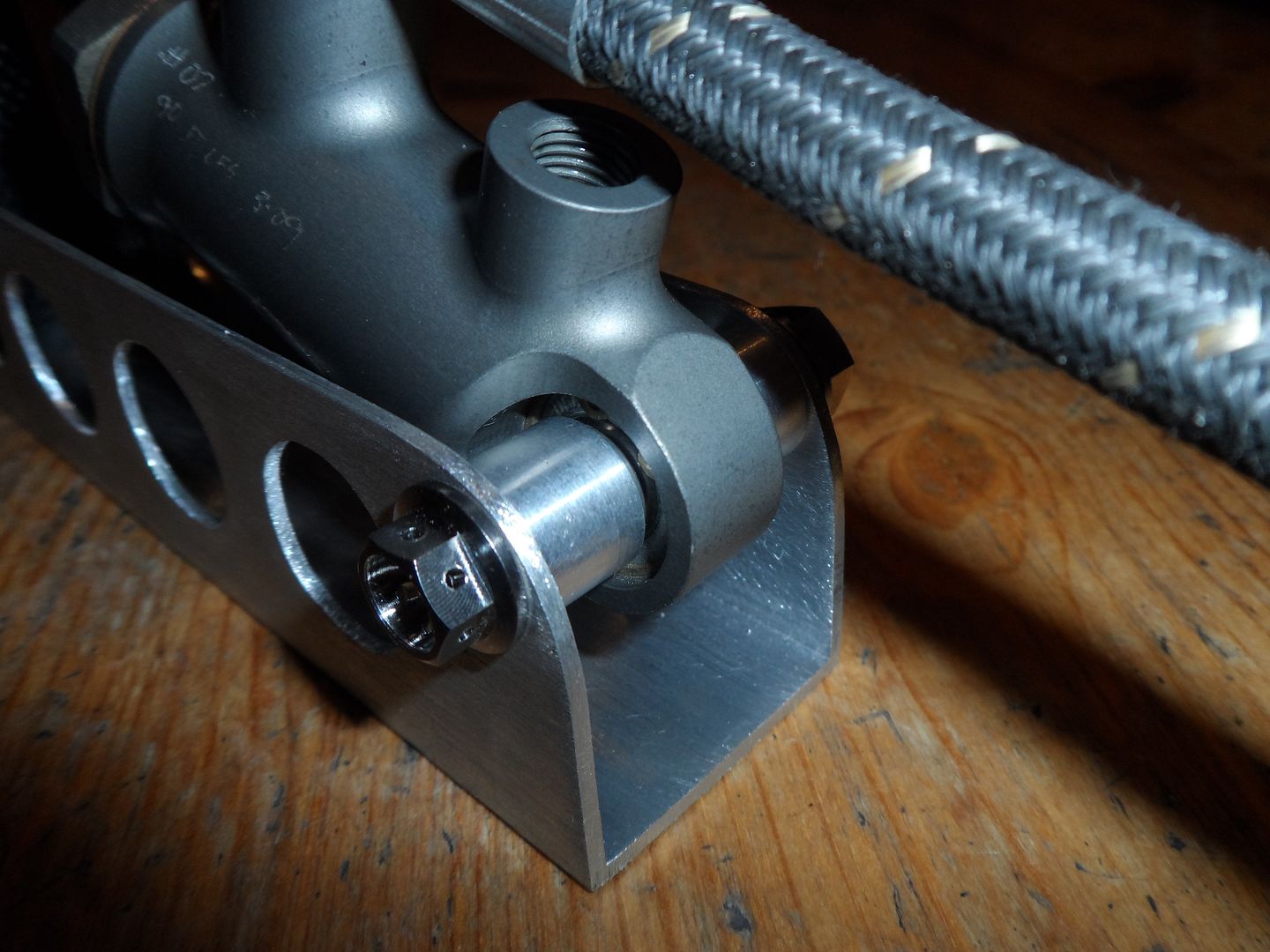

Hamish has been cracking on with the work on the rear diff pick ups. First job was to machine up some bosses. Decided to go up from the factory M10 bolts to use M12 x 1.5 fine pitch for a little more strength. Drilled out so there will be a male piece to slot inside so its not relying totally on the bolt like a factory sub frame. Machined to be a sweat fit into the tubing then they got tig'd in place.

Next job was to get the welder out again and weld some more metal to the jig to position the 4 diff pick ups centrally across the car and spaced to where he wanted the diff inline with the arch tubs. There is some play left with the diff brackets so he can fine tune that later on.

Then it was time to tie the 4 bosses into the cage, so more cutting and notching!

So that's the rear diff pick ups more or less done. Debating joining the front bosses into the rear ones to stop any fore and aft movement in the rear section. 2 outer bosses left to go in at the rear to take the anti roll bar. That will see the rear section finished off and he can move onto the the bigger gearbox tunnel.

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

SVM 286

Member

Registered: 13th Feb 05

Location: pain

User status: Offline

|

Frankly bloody amazing.

Does Hamish have specs from Audi for these builds Daniel, or does he magic all this crazy shit up in his head?

Either way, he's the Rainman of welding, fabrication and metal work.

So envious of his vehicles and his talent. And his workshop

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

quote:

Originally posted by SVM 286

Does Hamish have specs from Audi for these builds Daniel, or does he magic all this crazy shit up in his head?

Just what's available on the net. 320mm from behind B pillar. Done that size I think as the chassis rails pretty much meet back up at that measurement.

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

Hamish hasn't worked on the shell a great deal over summer as the weather has been far too nice and shell fabrication is horrible in hot weather! Will get back onto it full tilt over the winter months as the other car will be off the road so cant take up any time!

He has managed to get a little done on it. The rear tunnel had to go in before the cage tubing could be welded into place. This is again raised as per the rear floor to allow everything to run higher in the shell. Looks far better with the tunnel in as it links the 2 halves together visually. Then he completed the rear pick ups with the outer bosses. These will have a cradle going to the bottom of the rear diff to stop it twisting and he will also mount the rear anti roll bar on them that's why they are pushed back from the inner pick ups.

Going to complete the welding on the rear end and work forwards to complete the front tunnel and then extend the cage up to the front turrets and subframe pick ups. Should have more regular updates from now on!

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

He's back on this project now as the other car is off the road for the winter. Started moving forwards through the shell as the rear end is more or less complete now from a roll cage point of view.

First job was to cap off the holes in the sills where the main hoop drops down through the floor.

This was the gap to fill:

Cut and shaped some infill pieces:

This was welded into the sill and a 3mm spreader plate added to the other side.

3mm spreader plate on top of the in fill piece to get the required 120 cm2 of plate.

Welded into position:

Repeated on the opposite side, now doesn't look like 2 halves of the car:

The next job he moved onto was to jig up the steering rack position so the larger tunnel could go in and also to raise the steering mount:

Sits on the centre of the cross bar for the top mount pick ups.

Jigged up all 4 holes on the bulkhead as 2 are for RHD and 2 for LHD.

So with that point tied into the jig the tunnel and mount were cut out. The tunnel is higher than standard to take into account the raised engine and drivetrain. Its also widened out at the mouth on the right hand side right up to the chassis rail so it can give the exhaust a much easier path.

Tunnel folded up to suit:

Tried a seat in, all looks good!

Next job was to remove the firewall as it wasn't worth welding all the holes and sorting it for left hand drive.

New firewall cut to fit and sprayed with weld through primer to protect the closed edges.

And welded into place:

Rain tray was chopped out as it was just excess weight.

Final job was to make a new steering bracket. Decided to make a new one rather than adapt the original to fit. Started off with some curved tube bolted up to the jig and then built it back to the firewall.

All welded up on the jig:

Quick coat of paint before it was sealed up with a backing plate which would sit through the firewall.

Welded into place raised up 50mm then the jig removed:

Bars added down from the A pillars to tie the bracket into the cage and to stop anything from coming back through the bulkhead:

That brings it up to date so far. He's moving onto the front section of the cage next which starts with some more billet top mounts to raise them up same as the rear ones. Then the cage will be tied down into the front subframe points. Its finally starting to look a little more complete now it doesn't have so many large holes in the floor pan or bulkhead!

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

--ToM--

Member

Registered: 23rd Nov 07

Location: Wirral

User status: Offline

|

Absoloutely epic !! Fair play!!

Just been watching this

http://youtu.be/ERPEyfV0RC8

Awesome

|

taylorboosh

Member

Registered: 3rd Apr 07

User status: Offline

|

Amazing tbh

|

seanmooney

Member

Registered: 16th Nov 07

User status: Offline

|

Is this hamish's build? I watched the first build on edition 38 is this the second one?

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

Yeah this is Hamish's... v2

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|

Daniel_Corsa

Premium Member

Registered: 21st Apr 04

Registered: 21st Apr 04

Location: Wigton, Cumbria

User status: Offline

|

He hasbeen working away on the shell over the past few months. First job was to do the seat rails. He wanted them nice and low as he's tall so like to be well down inside the car. First job was to weld some spreader plates in, then sliced through the high point on the floor to get them to touch so it could be stitched into it for more strength.

Rails are 50 x 25mm box and the bolts pick up right through the floor to make access easier as that's something that's bugged me on the other car.

Next he moved onto finishing the mounting of the steering rack. Obviously it was right hand drive to begin with so the inner arch on the left required modifying so the rack could be bolted through it and also 50mm higher as per the centre mount.

Also extended the steering arm hole 50mm higher at the same time.

The opposite side had the RHD steering mounting and it had all sorts of bulges which he didn't like so that got chopped out and a new piece let in.

Finally moved onto the top mounts. Same as the rear lathed some up out of billet.

Couldn't get them as high as wanted as the bonnet limits them even with the bulge on the S1 E2 bonnet. They are offset rearwards by 25mm to give more caster angle.

Couldn't go back any further with them.

Had mentioned to a good mate about buying an AP racing handbrake as he was starting to mount up all the driver controls. He convinced Hamish that he should make one, said it would be much nicer and a lot cheaper! Well its probably cost a lot more with labour but it has turned out rather well!

Uses a 25mm carbon shaft with an alloy insert in the base to help with the loading. Its bored up the centre so its super light.

Shaft uses a bike grip and an alloy plug to finish it off.

All bolted together with titanium bolts, nuts and washers. Shaft pivots on roller thrust bearings.

Now the top mounts are in he's going to get them tied into the cage and then from there drop down and pick up the front subframe points. Hopefully get a bit done over the festive period!

April '06' Corsasport Feature Car  | Aug '08' Total Vauxhall Feature Car | Aug '08' Total Vauxhall Feature Car  | Spring '09' Fast Car Feature Car | Spring '09' Fast Car Feature Car

|